製品説明:

自動ワイヤーシェルフ溶接機は,近代製造業の増大する需要を満たすために設計された先進的で高効率のワイヤーシェルフ生産機械です.この最先端のワイヤーシェルフ溶接機械は 自動化技術と精密エンジニアリングを統合し 卓越した品質のワイヤーシェルフを 卓越した速度と一貫性で提供します製品品質の最高水準を維持しながら,生産プロセスを最適化したい企業にとって理想的なソリューションです.

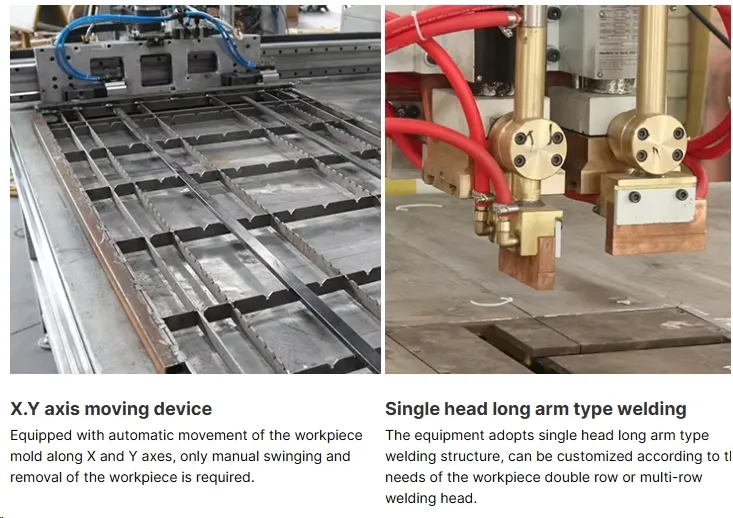

この機械は自動製の 棚のワイヤ 溶接機として 完全に自動化された操作を可能にする 最先端の機能で 装備されています人工労働の必要性を大幅に削減し,人間の誤りを最小限に抑える自動化により,各ワイヤレフが均等な強度と精度で溶接され,耐久性があり信頼性の高い完成品が作れます.これは生産効率を向上させるだけでなく,製造環境の全体的な安全性とエゴノミクスも向上させる..

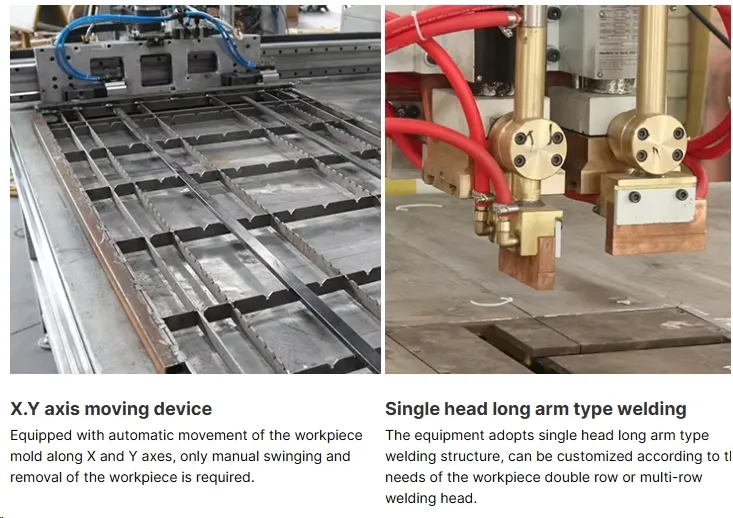

このワイヤーシェルフ生産マシンの主要な利点の1つは,その汎用性です.それは様々なサイズと種類のワイヤーシェルフを溶接することができます.リテールなどの産業における幅広い用途に適しています機械の適応可能な設計により,製造者は特定の顧客要件を満たすために棚の寸法と構成をカスタマイズできます.製品提供の柔軟性を高めること.

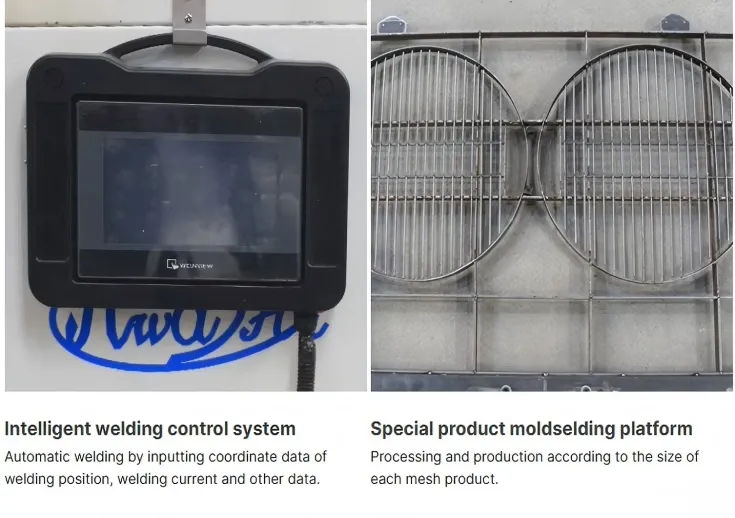

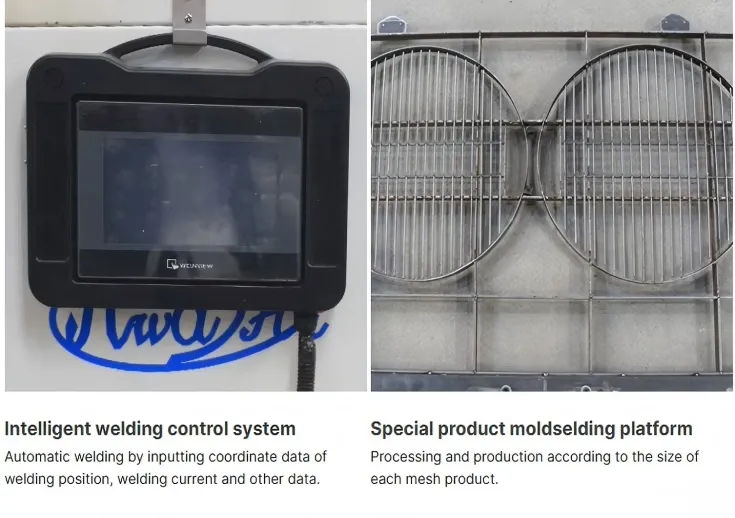

ワイヤーシェルフ溶接機は,長期耐久性と最小限の保守を保証する高品質の材料で堅牢な構造を誇っています.操作者は簡単にパラメータを設定し,リアルタイムで溶接プロセスを監視することができます.この直感的なデザインは,トレーニング時間を短縮し,生産出力を最適化するために迅速な調整を可能にします.

機械的な卓越性に加えて,自動棚ワイヤ 溶接機は 操作者と機器を保護するための高度な安全機能を組み込みます.事故を防止し,スムーズな動作を保証するために機械に統合されていますこれらの安全対策は,生産性を最大化しながら,安全な職場を維持するのに不可欠です.

このワイヤーシェルフ生産機械の効率は,高速溶接能力によってさらに向上します.それは同時に複数の溶接を実行することができます.伝統的な手動溶接方法と比較して,抜流量を大幅に増加させるこの高い生産率は,生産者が厳格な期限を満たし,品質を損なうことなく事業を拡大するのに役立ちます.

さらに自動ワイヤレフ溶接機は エネルギー節約技術で設計され 消費電力を削減しますカーボンフットプリントを減らすことを目指す企業にとって 環境に優しい選択肢になる効率的な設計により,材料の廃棄も最小限に抑えられ,コスト削減と持続可能な製造方法に貢献します.

このワイヤーシェルフ溶接機械のもう一つの重要な特徴は,既存の生産ラインに簡単に統合することです.そのコンパクトな足跡とモジュール式設計により,シームレスな設置と他の自動機器との互換性この柔軟性により,製造業者は作業流程を合理化し,全体的な運用効率を向上させることができます.

簡単に言うと 自動ワイヤーシェルフ溶接機は ワイヤーシェルフ製造技術の重要な進歩を象徴しています信頼性と高性能のワイヤーシェルフ生産マシンを供給するために商業用棚,ストレージラック,またはディスプレイシステムのためのワイヤー棚を生産しているかどうか,このワイヤー棚の溶接機械は,速度,品質,そして多用途性.

この自動棚用ワイヤー溶接機を選ぶことは 生産能力を向上させるだけでなく 一貫した製品優質性を保証する 機械に投資することを意味します革新的な特性と堅牢なデザインにより,今日の急激な市場において競争力を維持することを目指すすべてのメーカーにとって不可欠な資産となりますこの最先端のワイヤーシェルフ生産機械で 自動化と優れた溶接技術の恩恵を体験し 製造能力を次のレベルに高めましょう

特徴:

- 高効率の自動シェルフワイヤー溶接機 安定した溶接品質

- 高度な制御システムを持つ完全に自動的なワイヤーシェルフ溶接機

- 精密自動シェルフ溶接装置

- 耐久性と長寿を保証する堅牢な構造

- 操作と監視を容易にするユーザーフレンドリーなインターフェース

- 調整可能な溶接パラメータ,異なるワイヤサイズと材料に対応

- 溶接過程中の操作者を保護するための統合安全装置

- 様々なワークショップ環境に適したコンパクトな設計

- エネルギー効率の良い運用で 総生産コストを削減する

- 高速溶接能力があり,生産性を高める

技術パラメータ:

| 製品名 |

オートマティックワイヤシェルフ溶接機 |

| システムタイプ |

ワイヤーシェルフの溶接システム |

| 機能 |

電線棚の製造のための自動シェルフ溶接装置 |

| 溶接方法 |

抵抗 溶接 |

| 線直径範囲 |

2mm - 6mm |

| 棚の最大サイズ |

2000mm × 800mm |

| 生産能力 |

時速20台まで |

| 電源 |

220V / 380V,50/60 Hz |

| 制御システム |

触覚画面インターフェイスによるPLC制御 |

| 機械の寸法 (LxWxH) |

3500mm × 1500mm × 1800mm |

| 機械の重量 |

1500kg |

| 自動化レベル |

完全に自動的なワイヤーシェルフ生産機械 |

応用:

HWASHI HS-HC-1-7自動ワイヤーシェルフ溶接機は,ワイヤーシェルフ溶接装置の効率的かつ高品質な生産のために特別に設計された先進的なワイヤーシェルフ溶接機器です.この機械は,小売などの様々な産業で使用されるワイヤー棚の生産に焦点を当てたメーカーとワークショップに理想的ですCE,CCC,ISOの認証により,HWASHIブランドは,自動ワイヤー棚溶接機が安全性と性能に関する国際基準を満たしていることを保証します.生産能力を向上させたい企業にとって信頼性の高い選択肢となる.

HWASHI HS-HC-1-7 モデルは,精度と自動化が重要な場合に最適です.労働コストを削減し,生産効率を向上させるのに役立ちますスーパーマーケット,産業用貯蔵システム,または家庭用棚のためのワイヤラックを生産しているかどうか,このワイヤシェルフ溶接機器は一貫した溶接品質と速いサイクル時間を提供します.大量生産の需要を支える自動化機能により,人間の介入を最小限に要求するシナリオに最適化され,作業場の安全性を向上させ,エラーを削減します.

支払いの後7~30日間の柔軟な配達期間により,HWASHIの自動ワイヤーシェルフ溶接機は,さまざまな生産スケールを持つ企業のニーズに迅速に対応することができます最低注文量は1セットで,大規模な初期投資なしで設備をアップグレードしたい小規模企業にとって最適です.価格は交渉可能です.顧客が予算とニーズに応じて購入を調整できるようにするL/C や T/T などの支払い方法は,国際購入者にとって便利な金融オプションを提供します.

さらに,このワイヤーシェルフ溶接機器のパッケージは,海に適した木製のパッケージで行われます. 遠距離輸送でも安全で到着することを保証します.HWASHI HS-HC-1-7モデルでは 堅牢なエンジニアリングと 費用対効果の高い生産を組み合わせています世界市場での競争力のある選択肢です

簡単に言うと,HWASHI 自動ワイヤレフ 溶接機は,ワイヤレフの生産に関与する企業にとって完璧なソリューションです.大量生産を必要とする工場環境で優れています品質保証のための国際認証を提供し,柔軟な注文と支払い条件をサポートします.その高度な自動化機能は,それを必要不可欠にします 現代のワイヤレフ製造プロセス製品品質と運用効率を一貫して確保する.

サポートとサービス

自動ワイヤレフ溶接機は,ワイヤレフの生産において高効率と精度を保証するために設計されています. 最適なパフォーマンスと機械の長寿を確保するために,私たちは包括的な技術サポートとサービスを提供します.

技術サポート:

経験豊富な技術者のチームは,あなたの自動ワイヤーシェルフ溶接機の設置,校正,トラブルシューティングを支援するために利用可能です.機械の能力を最大限に活用するために詳細なユーザーマニュアルと操作ガイドを提供します.

メンテナンスサービス:

定期的な保守は,溶接機の円滑な動作に不可欠です.我々は,検査,清掃,潤滑,予期せぬ停止時間を防ぐために,磨かれた部品の交換.

パーツ供給:

本物のスペアパーツを備えており,迅速に交換し,機械の停止時間を短縮します. オリジナルパーツを使用することで,互換性と溶接質が保たれます.

訓練

機械の安全・効率的な使用を保証するために 操作員やメンテナンスのスタッフに 総合的なトレーニングをします 機械操作,安全プロトコル,定期的なメンテナンス障害解決の技術です

アップグレードとカスタマイズ:

製造ラインを最新に保つために 自動ワイヤレフ溶接機の ソフトウェアとハードウェアのアップグレードを提供しています特定の生産要件を満たすためにカスタマイズオプションも利用できます..

保証と販売後のサービス

製造上の欠陥をカバーする保証が付与されています. 販売後のサービスチームは,業務の妨害を最小限にするために,あらゆる問題を迅速に解決することにコミットしています.

当社の技術サポートとサービスに関する詳細については,機器に付属した製品ドキュメントを参照してください.

梱包と輸送:

商品のパッケージ:

自動ワイヤーシェルフ溶接機は安全な輸送を保証するために高品質の材料を使用して慎重に梱包されています.マシンは,最初に保護泡で包まれ,操作中に損傷を防ぐ顧客の要求に応じて,頑丈な木製の箱または強化された紙箱の中に入れます.すべてのアクセサリーと部品は,移動を防ぐために,パッケージ内の別々のコンパートメントに安全に梱包されます.簡単に識別できるように,パッケージには操作説明書と製品詳細が明示されています.

輸送:

私たちは,海運,航空運送,および急送サービスを含む,自動ワイヤーシェルフ溶接機械のための柔軟な配送オプションを提供しています.送料の方法は,顧客の場所と配送の緊急性に基づいて選択されます.輸送前に,機械は完全な動作状態であることを確認するために徹底的な検査とテストを受けます. すべての必要な輸出文書,商業請求書を含む,梱包リスト順調な清算を保証するために準備されています.当社の物流 チーム は,信頼 できる 運送 会社 と 連携 し て,お客様 が 指定 し た 宛先 に 迅速 で 安全 な 配送 を 提供 し ます.

FAQ:

Q1: 自動ワイヤーシェルフ溶接機のブランドとモデル番号は何ですか?

A1: 自動ワイヤーシェルフ溶接機は,HWASHIによって製造され,モデル番号はHS-HC-1-7です.

Q2: この溶接機にはどんな認証がありますか?

A2: 機械はCE,CCC,ISOの認証を取得しており,国際品質・安全基準の遵守を保証しています.

Q3:この製品の最小注文量と価格は?

A3: 最低の注文量は1セットです. 価格は注文量と特定の要件に基づいて交渉できます.

Q4: この機械を購入するには,どのような支払い条件がありますか?

A4: L/C (信託書) やT/T (電信送金) で支払えます.

Q5: 支払いの後に機械を納品するのにどのくらい時間がかかりますか? どのように梱包されますか?

A5: 配達時間は,支払いの受信後7~30営業日です.安全な輸送を確保するために,機械は海上用木製のパッケージに梱包されています.

![]()

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!